R&S®Essentials | Power supplies fundamentals

Understanding benchtop power supplies

Author: Paul Denisowski, Test & measurement expert

A fundamental understanding of dc power supplies and their basic functions is necessary for correct operations. The following will provide a general technical introduction to benchtop DC power supplies and explains the most important functions, parameters, and features of power supplies in modern test and measurement applications.

Most electronics are powered by direct current (DC), and therefore a DC power source or “supply” is required for almost all design, testing, and debugging of modern electronics. Although it is possible to use a fixed, non-configurable source of DC power, so-called benchtop or bench power supplies are normally used for this purpose.

There are many different models and configurations of benchtop DC power supplies, but there are some common requirements for almost any type of supply:

1. A variable, high-precision output:

- Voltage typically up to about 30V max

- Currents typically up to about 10A max

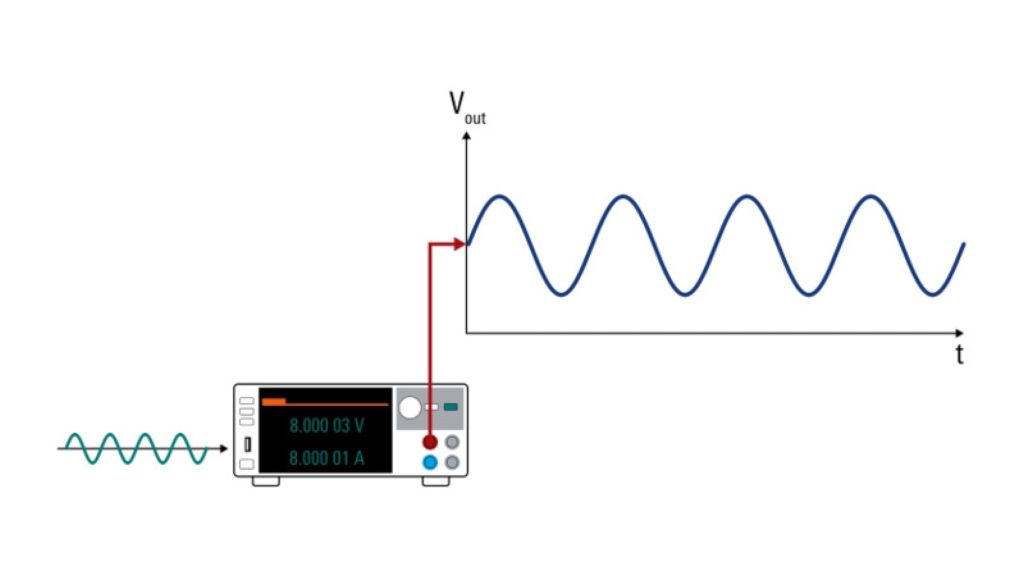

2. A high-quality bench power supply output: low noise and “ripple”

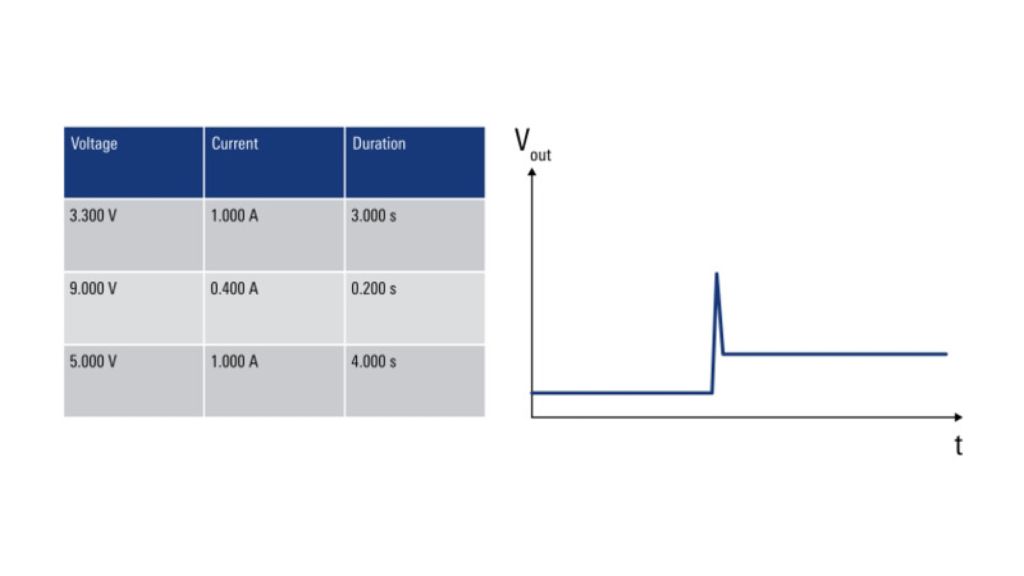

3. A low recovery time after a sudden change in load impedance

4. Multiple channels that can be used independently or combined

Basic specifications of benchtop power supplies

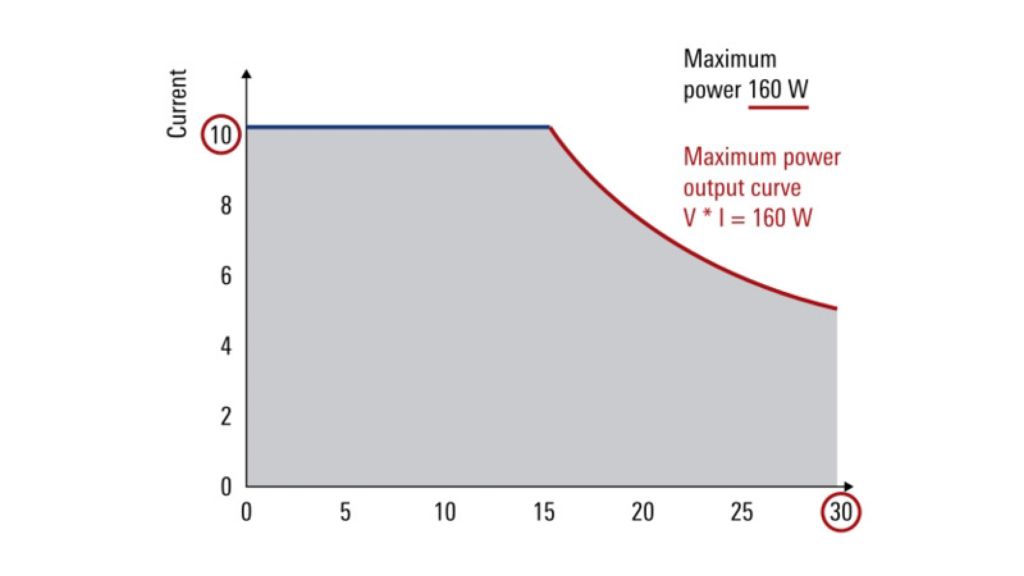

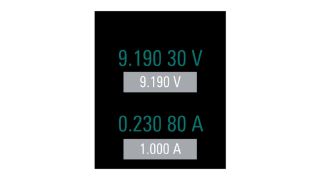

The most basic specifications of a power supply are the maximum output voltage (in volts), the maximum output current (in amperes), and the maximum output power (in watts). These are usually specified per channels.

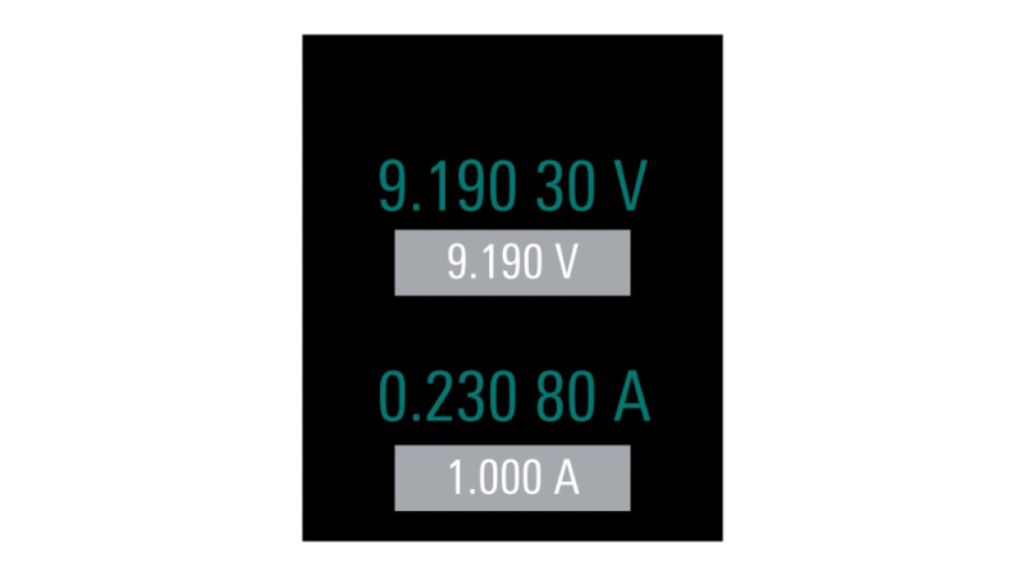

For example, this channel has a max voltage of 30V, a max current of 10A, and a max power of 160W. It is important to note that max. power is less than max. voltage times max. current. Here, the maximum channel power output is 160W, and not 300W.