Verifying DC-DC converter efficiency

Measuring efficiency with highest accuracy

Measuring efficiency with highest accuracy

Efficient use of energy is a key factor in many applications. Efficiencies above 90% are often required in a converter design. And highly accurate power measurements are necessary to optimize the converter. Designers need this capability to be able to improve converter efficiency during the design process in order to develop a highly efficient converter design that can be released to production.

Efficiency is often the key factor in power converters. This is true for battery operated IoT devices to get the most out of the battery, and it is also true for small DCDC converters supplied by a DC rail. Improved efficiency results in a smaller battery, which means the converter size and overall system cost can be reduced. This makes it very beneficial to measure the efficiency of a converter during the design process. To measure the efficiency of the converter, it is necessary to measure the input and output power with high accuracy. A designer can follow an incremental process to increase the efficiency of the design. This incremental process consists of several small steps where the designer has to evaluate the improvement in efficiency after each design modification. The evaluation of the efficiency value is a challenging task because the improvement of the efficiency is the sum of several relatively small changes in the design. It has to be possible to detect small changes in the power measurement in order to support the process of improving converter efficiency. It is essential to have equipment with highest accuracy for power measurements.

The R&S®NGM202 and R&S®NGL202 power supplies are perfect for challenging small power converter applications. Their two-quadrant architecture allows them to function both as a source and sink to provide highest flexibility. The highly precise read-back measurement capability for voltages and currents at the input and output offers the designer a very simple solution where only one device is required to measure the efficiency. There is no need for a DC supply, additional digital multimeters and an electronic load because the R&S®NGM202 and R&S®NGL202 power supplies feature everything in a single instrument.

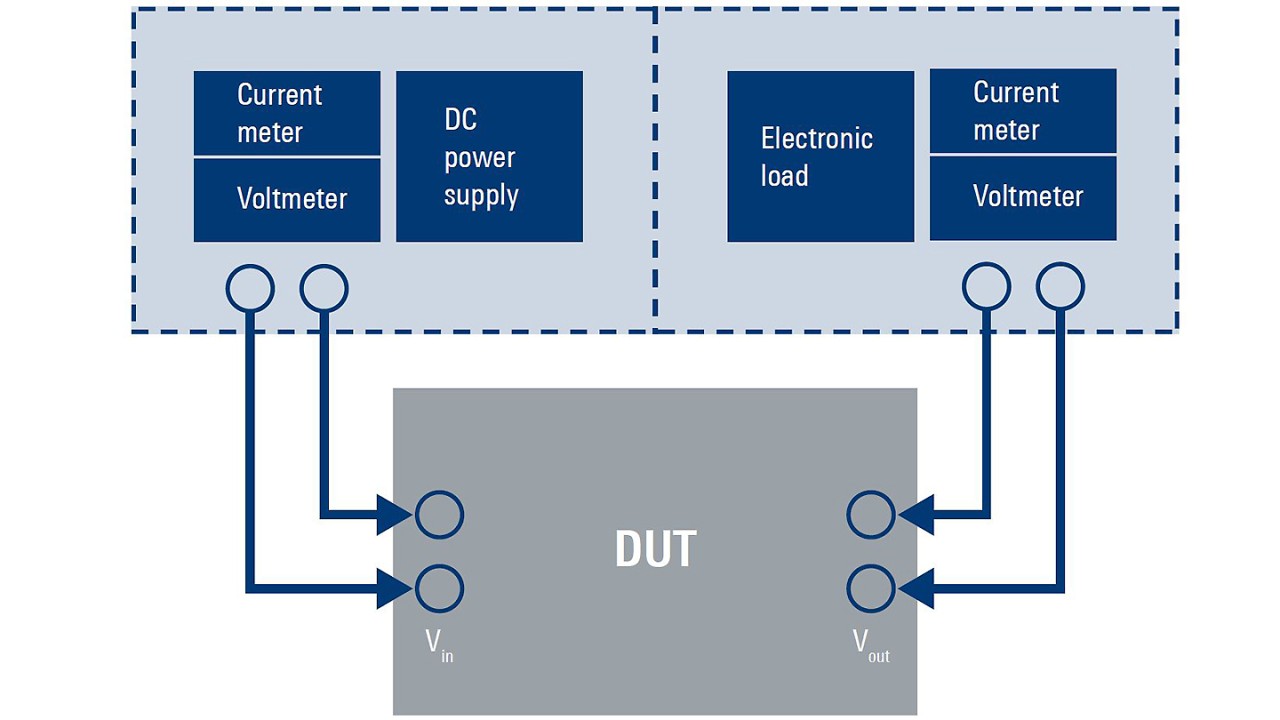

The measurement setup consists of the R&S®NGM202/R&S®NGL202 and the device under test (DUT) connected to the two channels. Optional remote sensing connections increase the accuracy at higher currents

Device setup

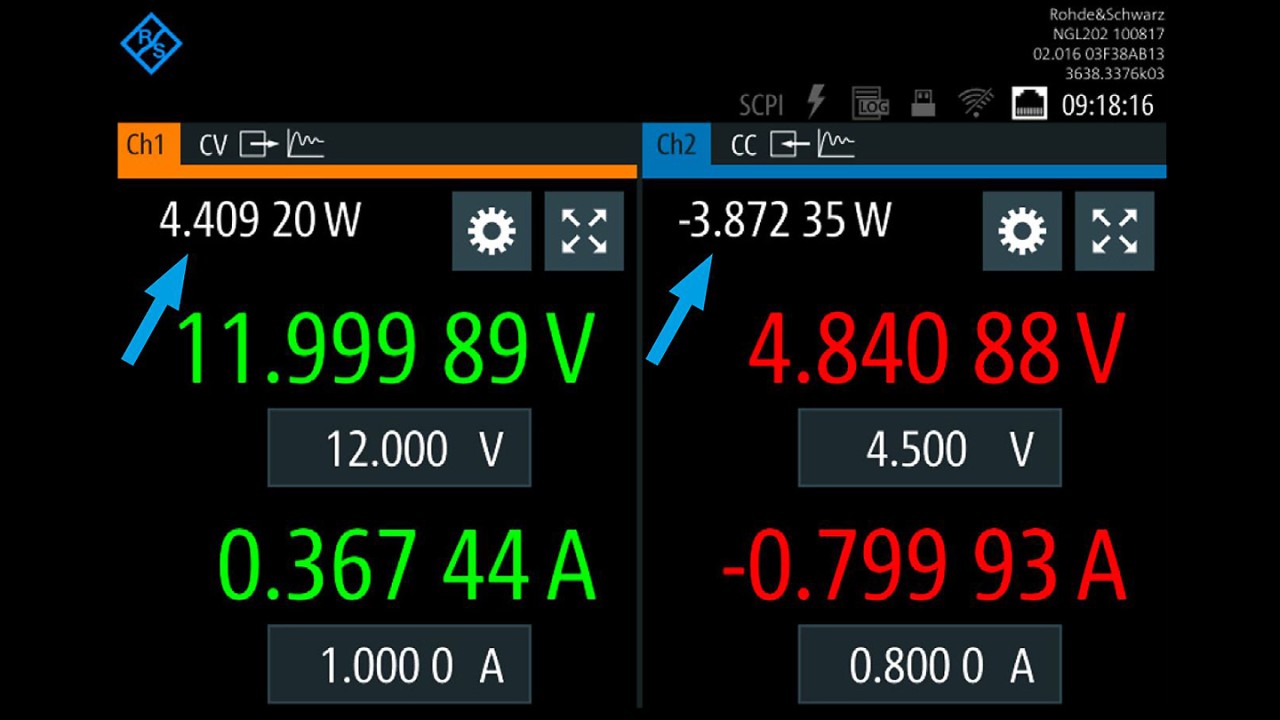

Channel 1 is configured to work as a constant voltage source that supplies the converter with the required voltage and current. The second channel is configured to operate as a load in constant current mode to load the converter with a valid operational current based on the converter specification. The voltage and current at the input and output are measured internally, and therefore the input and output power can be calculated and displayed on the screen.

Device configuration sequence

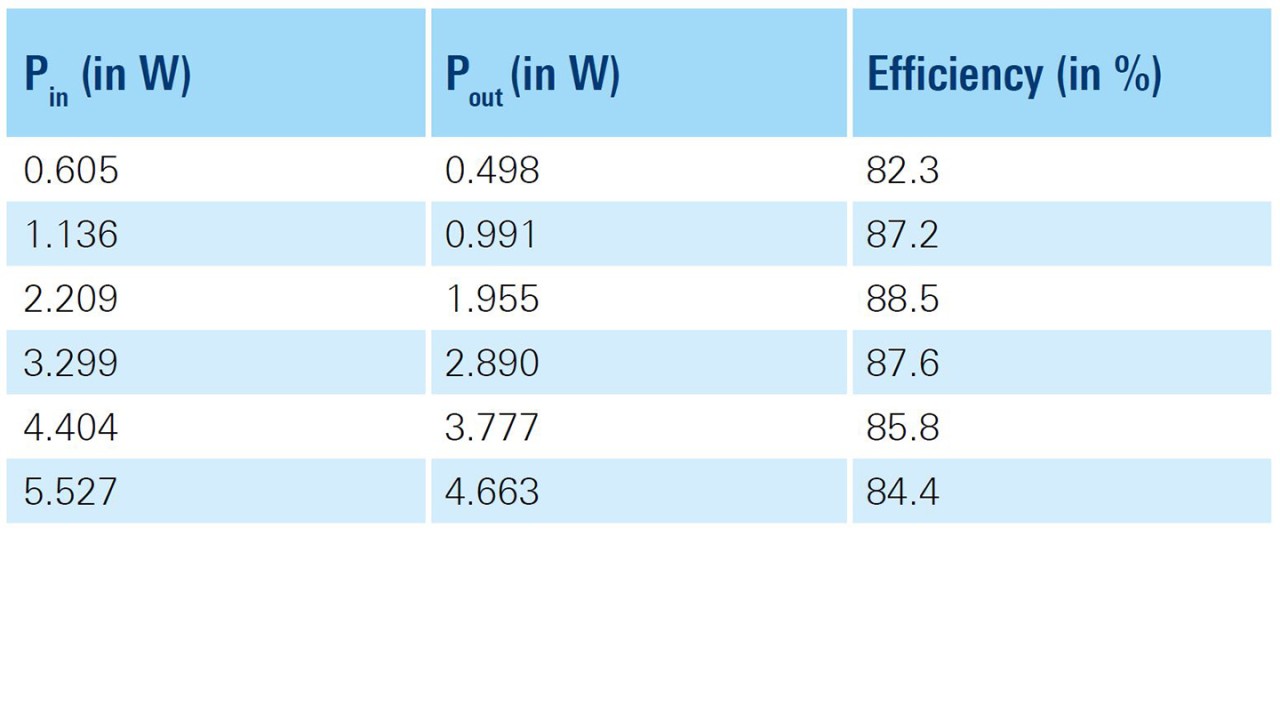

Case study – efficiency measurements on a 5 W DC-DC step-down converter

The efficiency measurements at different load conditions shown in the table above indicate that the converter is already an efficiency-optimized converter. Manufacturer data sheets for DC-DC converters usually only show specifications for ideal wiring. The R&S®NGM202/R&S®NGL202 lets you determine the efficiency of your individual circuitries and layouts. These values can deviate widely from the values specified in the data sheet.

This means that in addition to going through the discussed optimization process to improve efficiency, the designer has to perform multiple measurements to validate the efficiency under all circumstances. This effort can be reduced tremendously by using the remote control functionality of the R&S®NGM202/R&S®NGL202. For example, efficiency traces can be automatically created with an external script and a piece of software. This automated approach saves the designer time and also prevents the human errors that often occur during a manually performed process

The R&S®NGM202/R&S®NGL202 power supply solution offers designers great functionality and performance to measure, evaluate and optimize the important DCDC converter efficiency with just one instrument. This enhanced measurement capability will help them develop a highly efficient product design. It can also reduce time and effort during the development cycle.