Written by Arnd Sibila | updated April 26, 2024

Why are factories expected to become “smart”?

Factory owners aim to make the manufacturing process and production facilities more flexible and adaptable to reduce the cost of operations by minimizing downtime, achieved by modifying production lines, synchronizing inventory management, and efficiently organizing personnel and equipment.

ABI Research provided some outlook about private 5G networks in the RCR Wireless webinar "Private 5G for industry 4.0 - hype vs. reality" (March 2024):

- Private 5G is slowly maturing, evolving from an exploratory phase (trials & PoCs) towards real commercial deployments, leading to a more realistic picture from different angles

- Missing pieces are still: 3GPP Rel.16 and 17 capable, industry-grade chipsets and devices; convincing ROI and COI story for enterprises

- Macroeconomic conditions lead to a drastically shorter ROI tolerance within enterprises (<1 year)

- Market consoklidation is in full swing and new players entering (hyperscalers and System Integrators (SIs))

- Realistic value proposition for private networks: Providing connectivity for a large coverage area, mainly TCO driven

Thus, turning factories into smart factories becomes a commercial necessity because the “cost of inaction” will cause significant disadvantages to traditional factory owners; competitors with smart manufacturing will have less downtime while producing more.

What characterizes a smart factory?

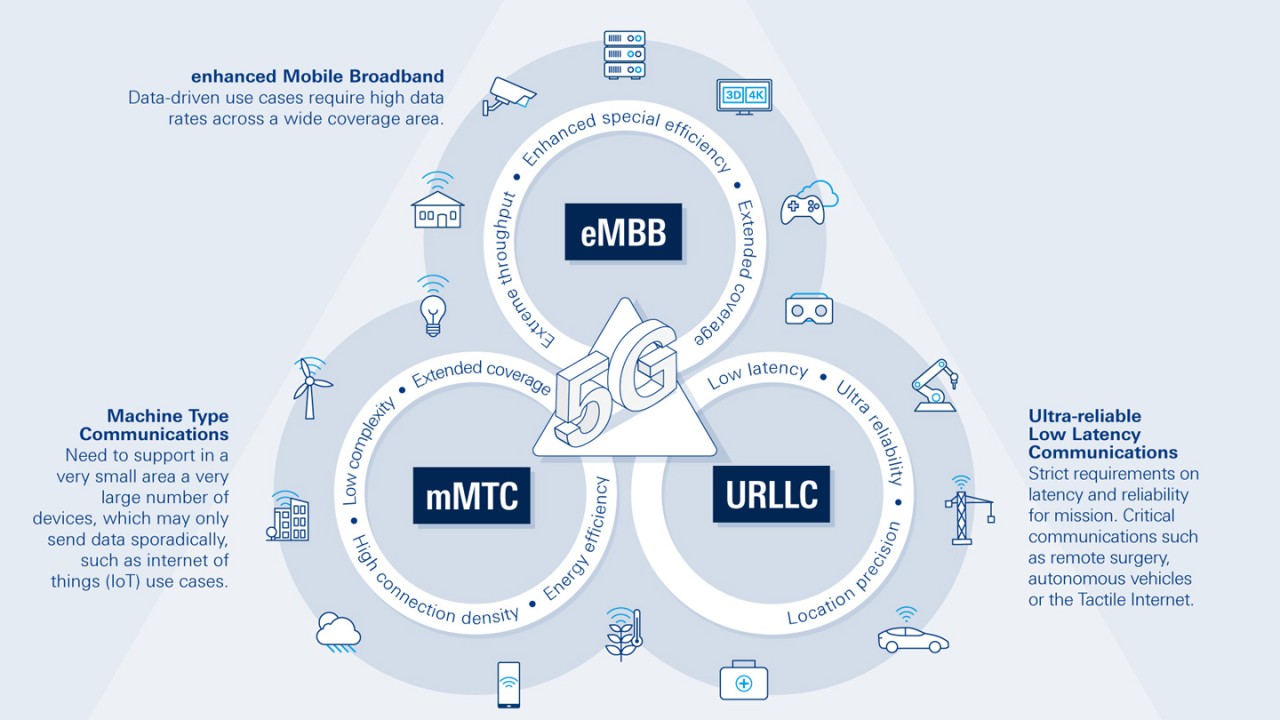

In a smart factory, many different use cases are assumed as specified in the well-known 5G triangle.

eMBB: Although we do not expect the need for very high data rates and capacities in smart factories, we see the need for augmented reality/virtual reality (AR/VR) use cases. AR/VR can increase operational efficiency in a factory due to the guidance of manual assembly, asset diagnostics for technicians, and training (i.e., human beings will get visible instructions to operate complex machines).

URLLC: Connected and collaborative robots are key tools to increase productivity in a smart factory. They should be able to work safely alongside human beings and execute repetitive tasks much faster with fewer errors. Self-driving automated guided vehicles (AGV) and autonomous mobile robots (AMR) improve factory logistics by automatically transporting goods in the factory and providing the right amount of material at every location. AMRs move autonomously, navigating safely between human beings and other objects.

mMTC: Smart factories rely on numerous sensors for inventory control, supply chain management, and predictive maintenance (to identify anomalies and decrease downtime). The information and data they provide will help to improve logistics. For mission-critical manufacturing, sensors will supervise the wireless connectivity in the factory and report any deviations from the targeted performance to a performance monitoring system in real-time.

Some of the factory and warehouse use cases described above can be and are already implemented with the LTE technology (4G). 5G is already available since a few years for public networks and also in use for private networks, but to make industry 4.0 applications successful in private networks the 3GPP Rel.16 and 17 ecosystem for chipset and devices need to develop further. Nevertheless, the key requirements for smart factories remain reliability, latency, and security.

Main KPIs of mobile networks in smart factories

A smart factory is a critical environment that needs to meet rigid requirements on the connectivity and reliability of machines and robots as well as on the data security and employee safety, especially if the connectivity is provided by wireless technologies. These requirements need to be checked, verified, monitored, and, if corrective action is needed, optimized.

The reliability of wireless connections is mostly realized by redundancy schemes (not only in the Core Network but also in the RAN). In a reliable private network deployment multiple radio units or access points are serving the same area in a coordinated way in order to limit interference among each other.

This redundancy concept needs to be verified with network testing solutions. Verifications should be made upon the smart factory rollout and every time after factory modifications, since they might affect the signal propagation significantly.

Latency, or the time a signal needs to travel through the system, is another crucial requirement of smart factory networks that needs to be carefully controlled. We distinguish between round-trip latency and one-way latency.

AR/VR use cases, for example, need low round-trip latency, because if the technician wearing AR/VR glasses moves his head, the image depicting instructions needs to update very quickly to ensure proper operation. Robot control, on the other hand, requires low one-way latency. The system sends an order to the robot, and the robot has to act immediately (e.g., stop movement); it is just one-way communication.

So far, we have observed in tests that the one-way latency does not typically equal half of the round-trip latency. Therefore, it is important to test and verify both latency options in smart factories.

Stay tuned for the next post in this series, explaining the different phases of network testing in smart factories and the corresponding test solutions. In the meantime, find educational videos and more information on our dedicated private network testing web page.