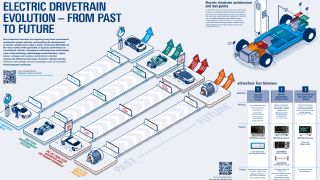

Solutions for traction inverter testing

The traction inverter is a vital element in the electric drivetrain that takes the DC electrical power from the battery pack and delivers AC power to the motor. It is responsible for accurately, safely and efficiently controlling the motor, thereby improving driving range, responsiveness, smoothness, traction and handling.

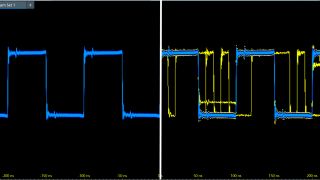

Traction inverter designers face numerous challenges, such as minimizing switching losses, maximizing thermal efficiency and ensuring EMI compliance when using wide-bandgap, high voltage semiconductors. These challenges can be better addressed with a robust test approach using optimum equipment.