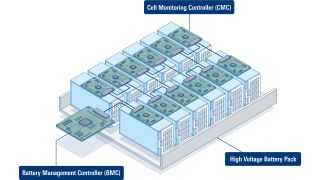

In Electric Vehicles (EVs) efficient cell-to-cell balancing is essential to ensure functional safety during charging and discharging and to optimize battery capacity. Battery Management Systems (BMS) help to control the power input and output of battery cells, modules, and packs.

In conventional BMS, the communication between the battery components is based on galvanic isolated wired daisy chain communication. Wired harnessing is the current industry standard, but limits the design flexibility and increases the weight of the vehicle and the required manufacturing time.

In a wireless BMS (wBMS), each battery module is interconnected via a Cell Monitoring Controller (CMC) to a Battery Management Controller (BMC) based on a robust wireless 2.4 GHz ISM band radio integrated circuit instead of a CAN bus cable or an isoSPI twisted pair connection. That simplifies the assembly, maintenance, and exchange of cells. While wBMS saves space and weight in-vehicle as additional benefits, challenges in testing are to be managed.

Rohde & Schwarz WBMS Test Solution

Automated test system, optimized for production lines

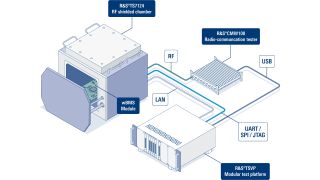

Rohde & Schwarz has developed together with Analog Devices Inc. (ADI) an ultra-compact automated test solution for wBMS. With this test setup all the necessary wireless BMS module calibration, receiver, transmitter and DC tests can be conducted fast and executed reliably for verification in the lab and for production tests ensuring highest yield.

The test system consists of the R&S®CMW100 Radio Communication Tester, the new R&S®ExpressTSVP Universal Test and Measurement Platform, and the R&S WMT Wireless Automated Testing software framework. Over-the-air testing of the DUT is achieved in an interference free environment using an isolated chamber such as the R&S®TS7124 RF shielded box.

Key features of the Rohde & Schwarz test solution

- R&S®ExpressTSVP cPCIe/PXIe-based modular instrument platform covering all non-RF wBMS interfaces and controlling the entire test bench including running the test automation software

- Parallel testing on up to 8x bidirectional RF ports of the R&S®CMW100 to further optimize asynchronous Tx and Rx tests and multi-module testing

- Complete crystal calibration & 16 channel Tx/Rx tests

- R&S®TS7124 or R&S®CMQ RF shielded chambers with isolation of up to 80dB

- Python based R&S®WMT wireless test automation framework optimized for production testing with easy customizable GUI for sequencing and test plan creation

- Easy 1-button test execution and automated HTML report generation

Benefits

- Easy integration of solution due to the use of standard R&S instruments

- Shorter test times through very fast DC and RF tests by the R&S®TSVP in combination with the smart channeling function (multi-port / parallel testing) of the R&S®CMW100

- Reduced maintenance effort due to in-system self-test and in-system calibration capabilities of R&S modular instruments

- Dust protected, space and energy efficient with ultra-small footprint

- World-wide service based on local application engineering support and customizable service level agreements

The solution built of proven test technology from Rohde & Schwarz, provides complete test coverage across all test cases and offers the speed and scalability necessary to ensure efficient testing from validation to production of highly complex wBMS modules.

To find out more, please get in contact with your local R&S representative.